Dental prototyping at CADdent®

Rapid prototyping on dental production lines

The digital workflows in the dental industry are very similar to the manufacturing processes for rapid prototyping. But not only the workflows are similar, also the uniqueness of the workpiece. Each dental framework is a unique piece that is individually made for its patient. Before a prototype can go into series production, it is also unique. The machine does not initially care whether it is producing a dental framework or a prototype. Therefore, prototypes and components for the industry can also be produced on dental production lines. We then speak of "dental rapid prototyping".

The parameters stored in our system for the manufacturing process are decisive for accuracy and fit. The manufacturing process for dental frameworks involves different requirements than those for jewelry, nozzles or other workpieces, for example.

Whether a prototype can be manufactured on a production line that is set up for dental devices is a decision on a case-by-case basis.

It is important that the design data is checked by experts and, if necessary, reworked.

Particular attention is paid to the shape and size of the object as well as the design and material thickness at the points that are decisive for the design.

Each dental framework is a unique piece and is individually adjusted and worked out by the dental technician. Manufacturing tolerances, such as those which arise in series production with subtractive processes, e.g. during milling, are already taken into account and minimized in the individual design on the CAD system. The difference between a series production of standard parts and a production system geared towards dental processes lies in the manufacturing process.

Processi di produzione utilizzati nell'industria dentale e per la prototipazione rapida

Sia nella tecnologia dentale che nella prototipazione rapida, si sono affermati nel processo di produzione i metodi di fabbricazione additiva, poiché ogni prodotto è un pezzo unico. I processi sottrattivi tradizionali, come la fresatura, presentano limitazioni nella libertà geometrica e un elevato consumo di utensili e materiali. I processi di produzione additiva, invece, presentano chiari vantaggi. È possibile realizzare quasi tutte le geometrie e risparmiare risorse grazie al consumo mirato dei materiali. Di conseguenza, è possibile produrre strutture dentali e prototipi per vari settori in modo economico.

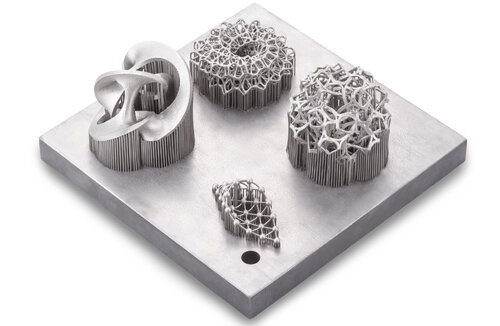

Dental rapid prototyping with selective laser melting (LaserMelting)

In the LaserMelting process, the design data - regardless of whether it is a prototype or a dental framework - is initially divided into individual layers by the system; this process is also referred to as "slicing". This step is necessary so that the individual layers can later be exposed in the laser system and thus fused together.

Read more about the LaserCUSING®, Laser Sintering, LaserMelting processes.

Dental rapid prototyping with lithographic 3D printing processes

The 3D printing process stereolithography (SLA) is very similar to LaserMelting (SLM). The main difference here is the material used. While dental prototyping through the LaserMelting process uses metallic materials such as cobalt-chromium (CoCr), titanium grade 5 or silver, stereolithography processes synthetic resin – also polymer. In other lithographic 3D printing processes such as Digital Light Processing (DLP) or Lithography-based Ceramic Manufacturing (LCM), the differences lie not only in the material used, but also in the energy source in the respective 3D printing technology. While LaserMelting and Stereolithography need a laser, the DLP or LCM process uses an LED module that selectively hardens the light-sensitive polymer particles. As with any 3D printing technology, the virtual slicing of the design is necessary prior to production so that the resin can be selectively cured under light irradiation and bonded together layer by layer.

When is dental rapid prototyping used?

Like so many things, rapid prototyping has its origins in the automotive industry. From there, the technology was quickly adopted for aerospace and medical technology.

Product designers have also recognized the advantages of rapid prototyping technology and use this process to manufacture representative prototypes or prototype parts. This is not only used for visualization, but also to develop and optimize production processes before series production begins.

Rapid tooling is a special form of rapid prototyping. Have you ever heard of Casting 3D in dental technology? Then you already know the procedure. With rapid tooling, an additive manufacturing process is used to produce a shape that is later used with another process, e.g. casting.

Dental rapid prototyping costs

The price for the production of prototypes is calculated individually on the basis of the designed 3D object. Basically, the material consumption as well as the space requirement on the construction plate of the dental production facility is decisive for this - thus the price is derived from the volume and the x, y and z dimensions of the component. Some manufacturing processes require reworking by skilled personnel / technicians, which is calculated according to the effort required depending on the size of the surface affected.

Our tip: Especially with prototypes that are only manufactured for illustrative purposes, it is advisable to construct them hollow and to allow for a small hole. In this way, production is resource-saving, because excess material can escape and the hole can then be closed.

CONCLUSION

Dental prototyping refers to rapid prototyping using dental production equipment. Both equipment and materials are suitable for many applications. You can discuss the specific situation with our specialists at any time. Our experts will be glad to advise you!

Update: In January 2022, we put our first ceramic 3D printing system into operation. Read more about this in the article Innovation Ceramic 3D Printing at CADdent.