Our 3D-printing - your plus

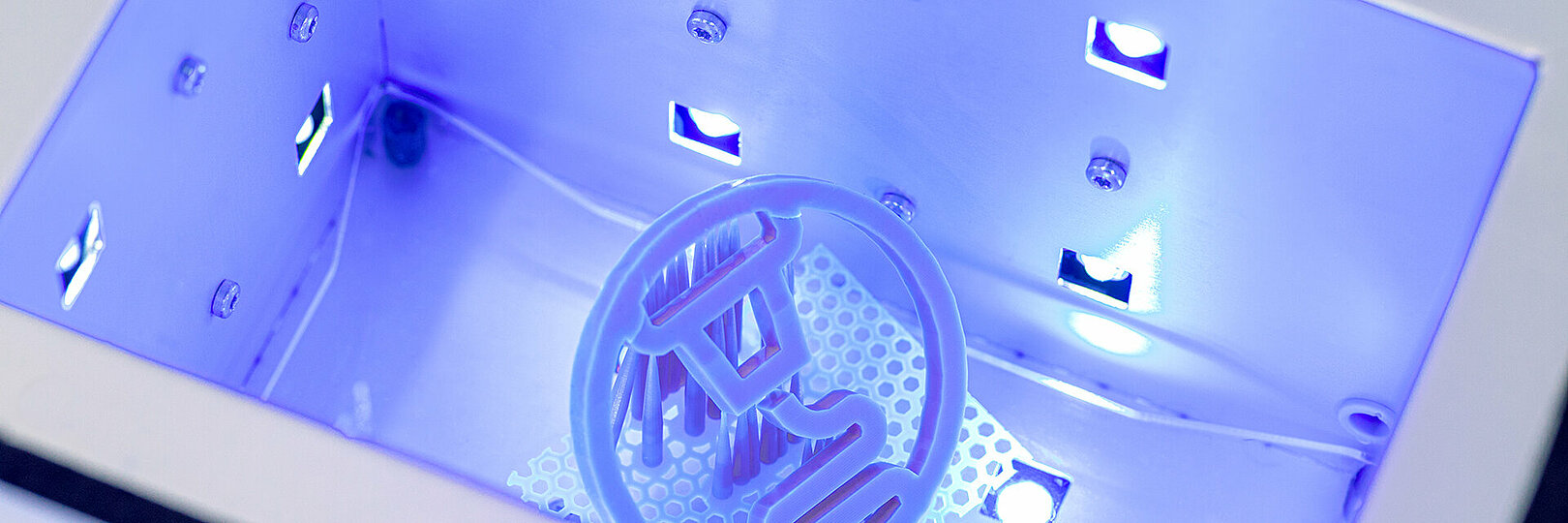

With our systems we implement the most complex designs in 3D-printing for the dental technology. Our equipment enables a wide variety of materials as well as a wide range of sizes for numerous fields of application, from printed models to printed impression trays and casting 3D.

3D-PRINTING

Our 3D-printing offers support laboratories in several ways: on the one hand by avoiding high acquisition and operating costs, on the other hand by the possibility of being able to offer interesting products such as impression trays and models.

Materials such as various resins in combination with several 3D systems and different 3D-printing technologies enable a wide range of products.

We use both liquid plastic processes (DLP) and plastic melting processes (filament). So you benefit from our selection without having to invest in different devices and material stocks. In any case 3D-printing is an extremely economical manufacturing process.

Only the material actually required is used to manufacture an object. The qualitative advantages of 3D-printing include high precision and reproducibility. The 3D design of the desired component is saved in STL format and "disassembled" into individual layers (slices) by the printer software, which control the actual printing process. The time required for standard products can be significantly reduced in the laboratory, additional organizational freedom is thus created. The health aspect at the workplace should not be underestimated either: grinding dust is a thing of the past.

THE ADVANTAGES OF 3D PRINTING

-

Excellent fit

-

Reproducible at any time

-

Any design can be implemented

-

Access to the latest material developments

-

Wide range of products

-

High variety of materials

-

Environmental friendliness through optimal use of materials

-

Fast production and short delivery times

-

Top price / performance ratio