Allergy free and versatile

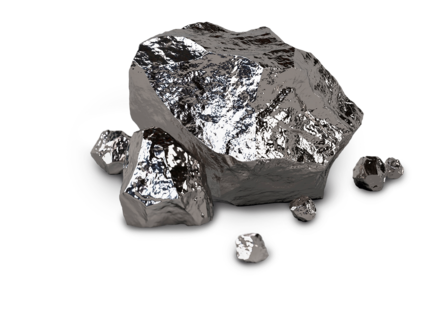

Our branded material Kera®Ti5-Powder (Made in Germany)

-

has the best biocompatibility of all metallic materials

-

offers a very good adhesive bond between the framework and the ceramic due to the lower alpha case

-

allows more delicate constructions than would be possible using conventional technique

The chemical element titanium (Ti) is considered a light metal. Its density is low, it is stretchy and resistant to corrosion and temperature.

Although it is rather soft in its pure state, it can achieve enormous strength with low weight even with the addition of small amounts of other metals in alloy.

In prosthetics, the material properties of titanium are ideal, but in the conventional casting process the material is very difficult to process, due to

strong voids or oxidation and only with the appropriate equipment. In contrast, we use titanium in LaserMelting very much indeed.

Titanium partial framework is characterized by a homogeneous material structure and delicate design options, since the process goes through the same safe production cycle as its nickel-free counterpart made of cobalt-chrome (CoCr). It is therefore superior to titanium casting, as it can be implemented in the laboratory.