Experience, Quality and Precision

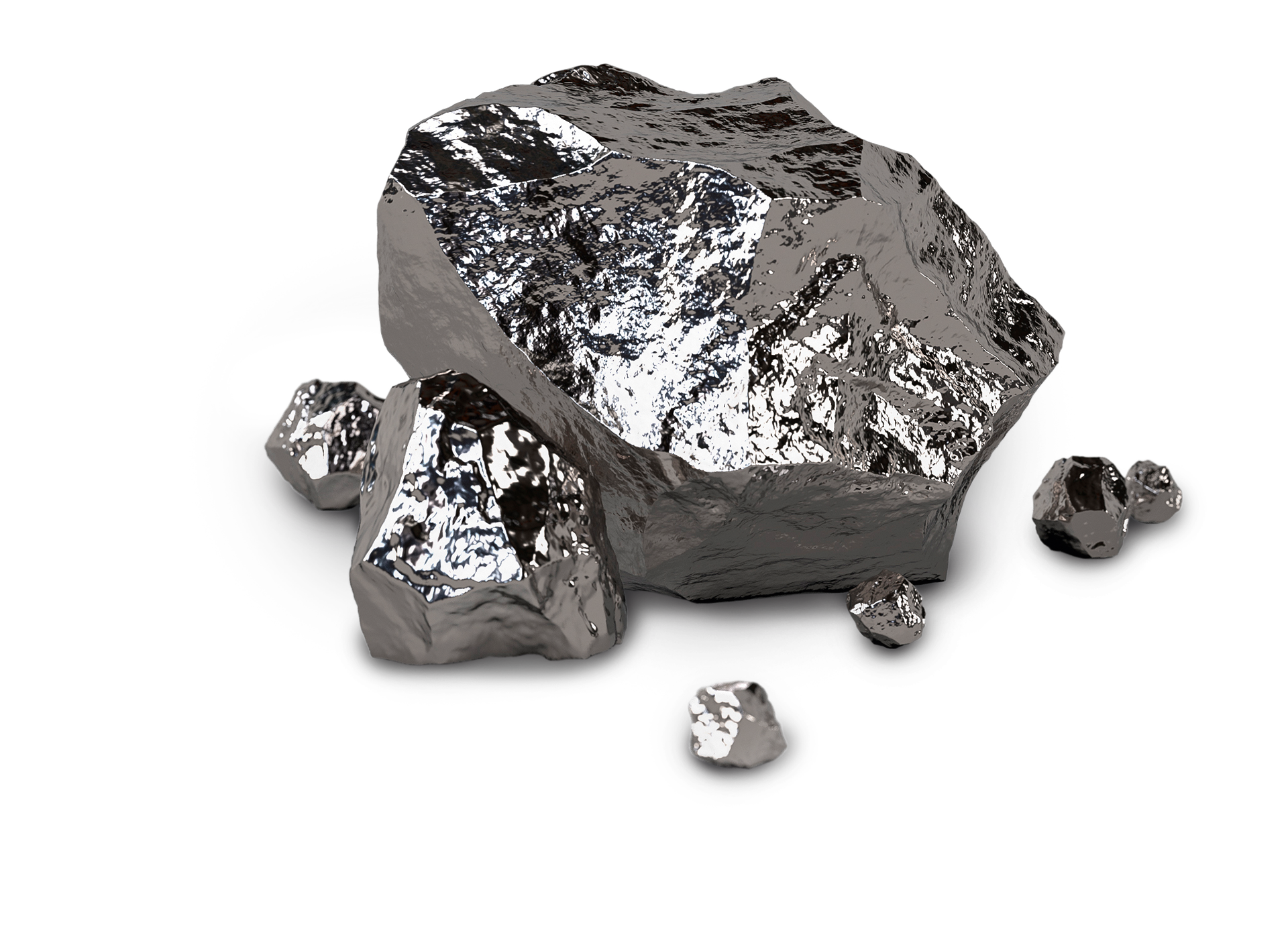

We are among the pioneers in selective laser melting (SLM) - a process that we just call LaserMelting. As a leading provider, we supply customers all over Europe with basic prosthetic products up to complex structures in orthodontics. Our LaserMelting process implements any digitally created 3D design in cobalt-chrome (CoCr) or titanium with high precision.

LASERMELTING

LaserMelting - also called Selective Laser Melting (SLM) - is an additive process that sets standards in filigree and precision. SLM is the successor to laser sintering. Metal powder is melted by laser and built up in the finest layers as a three-dimensional body. LaserMelting enables more complex geometries than any other method. The metal structure has the quality of laminated industrial steel and, in combination with its material properties, is superior to any dental cast. Large spans such as 16-unit restorations can be easily implemented in LaserMelting.

The process of lasering has been so extensively adapted to the requirements of dental technology that we achieve the highest possible fit - and with the fastest delivery times. Delivery variants give you the choice of the extent to which the product should be processed by us.

THE AVANTAGES OF LASERMELTING

-

Excellent fit

-

Any design can be implemented

-

Reproducible at any timr

-

Absolute homogeneity

-

Metal structure is like laminated alloys

-

Gaining space by eliminating the cutter radius correction

-

Hollow shapes and "digital scraping" for significant weight savings

-

Freedom from milling shadows and narrow interdental spaces

-

Accustomed processing

-

Environmental friendliness through optimal use of materials

-

Time savings for lucrative work, analog processes are eliminated

-

Fast production and short delivery times

-

Top price / performance ratio