Innovation LaserMelting Silver (3D printing)

CADdent was able to revolutionize the dental world in January 2019 with the LaserMelting Gold for the dental sector. In addition, the next milestone was set last year with the innovation of ceramic 3D printing. Now the research and development department is presenting the next innovation: LaserMelting Silver (3D printing).

CADdent as an innovative Rapid Prototyping Center

Our specialists not only test new procedures, but they also experiment with materials which go beyond the box of dental technology. It is important to us to promote the creativity of our employees. This expands our competencies and enables us to offer our customers the best possible quality and service. As a result, CADdent, as an innovative 3D printing and milling center, can convince not only in dental technology on a daily basis, but also in the field of rapid prototyping.

The 3D printing process LaserMelting Silver

Just like our cobalt-chrome, titanium or gold alloys, we now also process silver using the powder bed-based LaserMelting process. Before the start of the process, the desired object is placed virtually on a building board as a digital file and connected to it by supporting structures. In the next step, all set objects are digitally divided into layers. This process is called "slicing". The resulting layered information is then transferred to the production facility. Now the print job can begin. In the metal 3D printer, a thin layer of powder is first applied to a building board. A laser beam then selectively exposes the individual points at which a component or its support structure is to be created. The material is melted, which then connects to the underlying layer or, in the case of the first layer, to the building board. The process then repeats itself, creating the desired object layer by layer.

Silver for 3D printing: the material and its uses

The alloy used is 925 silver. This alloy is also known as sterling silver and is used in several areas. In addition to the production of jewelry and coins, components for various musical instruments are often made from it. Due to its very good electrical conductivity, silver is also used in electrical engineering.

Advantages of additive manufacturing

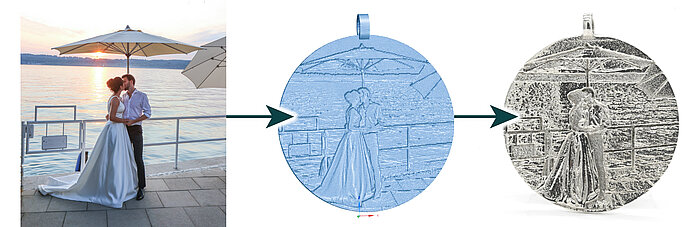

Processing using the LaserMelting 3D printing results in many advantages in every area of application. So-called additive manufacturing can be used to create thin-walled and complex structures that cannot be produced using conventional casting technology, for example. Components can be printed hollow, which significantly reduces material consumption and the associated costs and weight of the component. In addition, when producing a casting, it is first necessary to produce a casting mold in which sprues must be taken into account. In contrast, components in 3D printing are manufactured in a very material-efficient and resource-saving manner. Another advantage is the quick and easy customization option.

Designs can be digitally customized and adapted. Whether logos, images, fingerprints or animal paw prints - there are no limits to your creativity.

ARE YOU INTERESTED?

Our experts will be glad to support you with your projects, regardless of whether you just have an idea in mind or you already have specific design files. Contact us anytime here.