New in ceramic 3D printing: alumina-toughened zirconia (ATZ)

Alumina-toughened zirconia is becoming increasingly popular among technical ceramics. Due to their excellent material properties, ceramics have the potential to replace metals or polymers in many areas. The most commonly used technical ceramics include aluminum oxide and zirconium dioxide. New materials are constantly being researched in the field of additive manufacturing. Our in-house research and development department tests new materials at the development stage and compares them with the state of the art. This gives us a head start in terms of knowledge, which we use as a manufacturing service provider to be able to offer innovative materials at an early stage. This is also the case with alumina-toughened zirconia (ATZ), which can now be selected and ordered on our Rapid Prototyping order page. Find out more about alumina-toughened zirconia in this article and get a comparison with conventional zirconia.

Advantages of technical ceramics

Above all, the combination of very high strength, hardness and resistance to temperature, corrosion and chemicals make technical ceramics better and more durable alternatives to metals or polymers. The possibilities of additive manufacturing also mean that production limitations are eliminated.

High precision with LCM processes from Lithoz

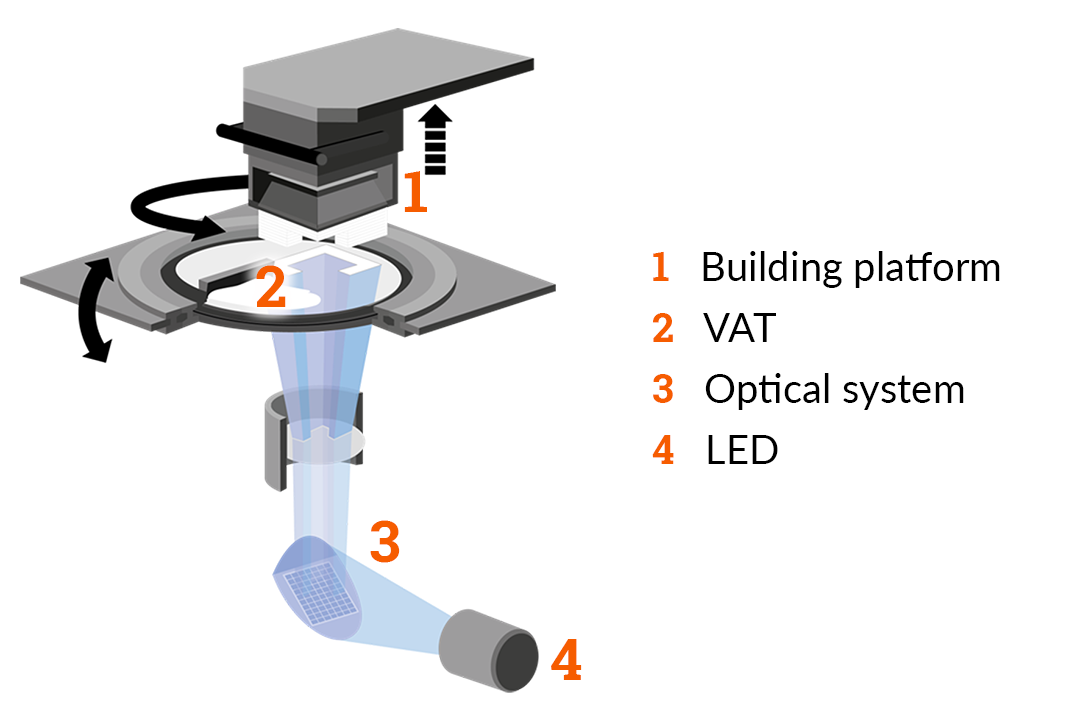

In the additive manufacturing of technical ceramics, CADdent relies on the LCM process (Lithography-based Ceramic Manufacturing) from Lithoz GmbH - the market leader in lithography-based ceramic 3D printing.

In this process, a mixture of liquid polymer and very fine ceramic particles is applied to a transparent tank. The building board is then lowered upside down into the tank and an LED module illuminates the layered image with blue light from below. The material is selectively cured by photopolymerization at the corresponding points where components or support structures are meant to be manufactured. This creates a layer bond to the previous layer or, in the case of the first layer, to the building board. In this way, the desired components are built piece by piece. These so-called green bodies must then be debinded and sintered. In this downstream thermal process, the polymer component is first burnt out and the ceramic component is sintered at the same time to form a dense ceramic.

Advantages of LCM technology

After the thermal post-process, additively manufactured ceramic components achieve a theoretical density of over 99% and have a surface quality of less than 1.0 µm. The LCM technology developed by Lithoz guarantees the production of highly complex structures with absolute precision and maximum resolution. For example, we are able to produce wall thicknesses of 0.15 mm and through-holes with a diameter of 0.15 mm from aluminum oxide. We can also achieve tolerances of less than 50 µm.

What is alumina-toughened zirconia?

The mixed oxide ceramic alumina-toughened zirconia consists largely - around 80 % - of zirconium dioxide. This is reinforced to a fraction of about 20 % with aluminum oxide. This allows to balance the respective disadvantages out and to combine the respective advantages of both materials.

Alumina-toughened zirconia (ATZ) vs. zirconia

The alumina-toughened zirconia is somewhat harder and lighter than pure zirconia due to its aluminum oxide content. Due to the high zirconium content, ATZ, like zirconia itself, has a very low thermal conductivity. With 3D printing of ATZ, we can realize smaller wall thicknesses (0.15 mm) and channels more precisely due to a higher resolution. In addition, much thicker walls are possible with ATZ compared to additively manufactured zirconia. With 3D printing of zirconia, there is a risk of cracking during the thermal post-process even with wall thicknesses of over one millimeter. In contrast, depending on the geometry, we can also produce wall thicknesses of over ten millimeters through 3D printing of ATZ. The reason for this is the easier degassing during thermal debinding, i.e. the burning out of the polymer component. As the manufacturing process is therefore more resistant to errors, we can offer 3D printing of ATZ at a lower price than 3D printing with zirconia.

How to order components in alumina-toughened zirconia (ATZ)

We are proud to expand our material portfolio in rapid prototyping in the field of ceramics and to be able to offer ATZ in addition to aluminum oxide and zirconia. Simply upload your 3D object as an STL file in the prototyping upload area. In the material overview you can directly see the corresponding prices and delivery times, which are individual to your component and depend on the desired material. We look forward to manufacturing your designs!

CONCLUSION

The alumina-toughened zirconia has many advantages over zirconia, which is why it is able to replace it in many industrial applications such as aerospace, electrical engineering and the automotive sector. As an innovative manufacturing service provider in 3D printing and milling of various ceramics, metals and polymers, CADdent is your work companion and expert - even for new materials such as ATZ.