3D-printed dental splints – revolution or risk?

3D-printed dental splints polarise opinion: some dental technicians and dentists consider them to be of insufficient quality, while others see them as an economically viable alternative. As is so often the case, the truth lies somewhere in between. However, with the introduction of splintmaster taff from detax, the boundaries between printed and milled are becoming increasingly blurred. In this article, we explain why we are now offering printed splints and how the new material overcomes old weaknesses.

The biggest difference between milled and printed splints is the material:

Milled splints are usually made of pure PMMA (polymethyl methacrylate), which is industrially cured and has stable, resilient properties.

3D-printed splints are made from light-curing polymers. Unlike PMMA, these mixtures consist of several ingredients which influence the material properties. And so far, nothing has come close to PMMA in this respect.

Despite the advantages of 3D printing – such as flexibility and time savings – the first generation of 3D-printed splints often caused problems in the practice and use. They had a higher content of non-polymerised monomers, which led to:

-

allergies,

-

unpleasant plastic taste,

-

increased plaque adhesion,

-

brittleness and

-

faster material wear.

It was not without reason that many laboratories and practices were wary of these products.

What has changed?

Essentially, the material. With the MDR-approved polymer splintmaster taff from detax, a material is now available which specifically overcomes the previous disadvantages of 3D-printed splints. This is due to significant advances in the raw materials used for 3D printing polymers. This field is still developing rapidly. Completely new possibilities have emerged in recent years. They allow to create splints with properties increasingly similar to PMMA, while at the same time offering greater flexibility and toughness.

-

Extremely low solubility (1.1 µg/mm³) – comparable to PMMA, which means:

- like PMMA, the splint is odourless and tasteless.

- as with PMMA, there is a minimised risk of allergic reactions. -

High toughness with just the right flexibility – more comfort, less risk of breakage.

-

Very good polishability and reworkability – similar to PMMA. Together with the low solubility, this reduces the risk of discolouration to a minimum.

-

It can be extended with all common cold-curing or light-curing plastics.

In other words: the new material offers the economic and procedural advantages of printing – without the previous functional or biological disadvantages.

What does this mean for your laboratory?

For us, it has always been clear that as long as 3D-printed splints do not meet our quality standards, we will not include them in our range of products. This situation has changed with splintmaster taff. The material properties are now so advanced that in many cases they can be used as an equivalent replacement for milled PMMA splints.

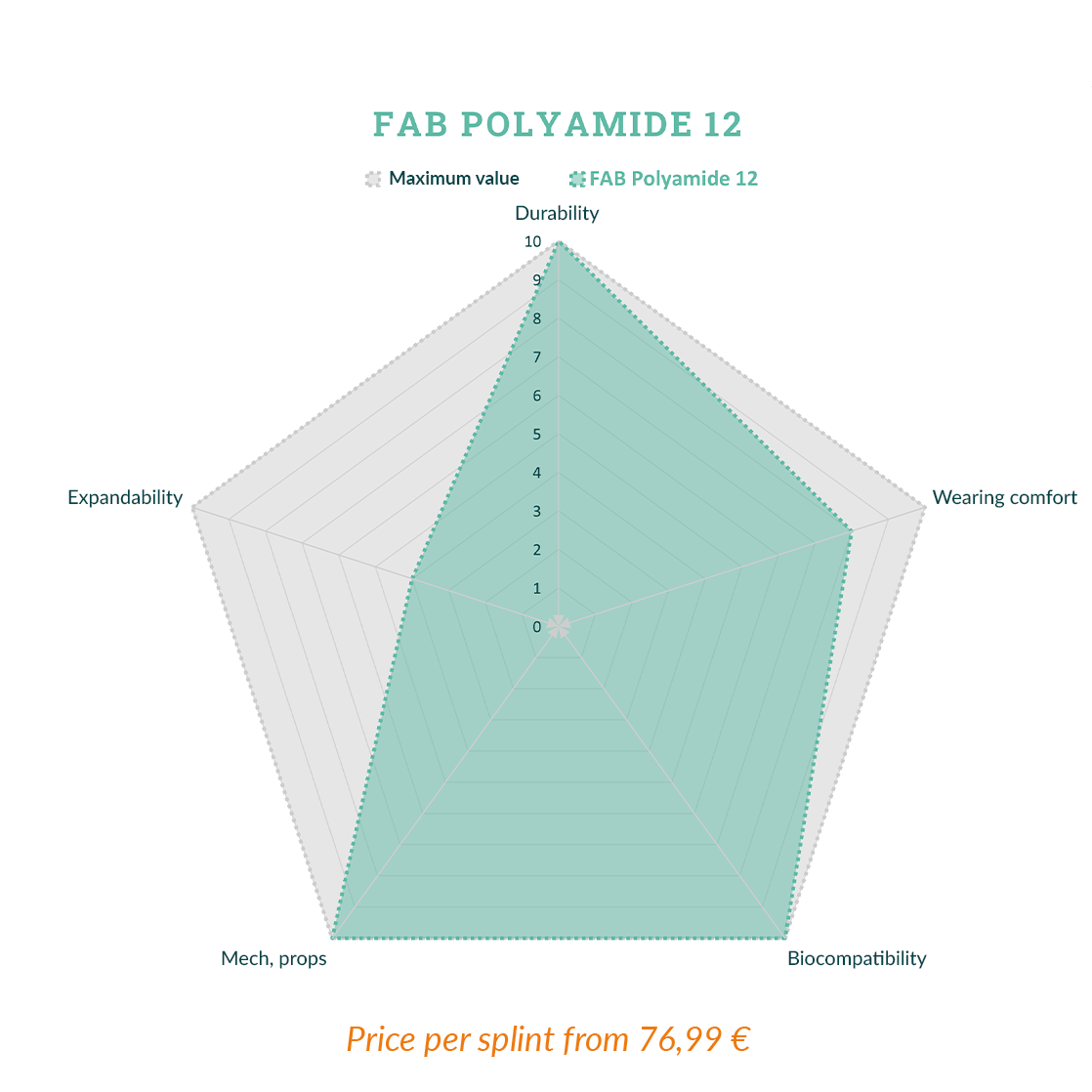

But we remain realistic. Splintmaster taff is not as comfortable as our FAB MSI FX or as indestructible and biocompatible as our splints made of FAB Polyamide 12. Nevertheless, it offers excellent value for money.

Price & Offer

-

Regular list price: € 44.99 | promotional price: 36,99 €

-

Standby discount (1 day longer production time): only 37,99 € | promotional price: 29,99 €

At this price, it's definitely worth giving it a try. Try it out on your next job and see for yourself the progress made in 3D-printed dental technology.

The fast production time of 3D printing allows us to produce splints one day faster than milling them. Send us the data set by 2 p.m. and it will leave our premises the next working day. For very urgent cases, we are even able to ship on the same day.

TO OUR PRICE LIST ORDER NOW

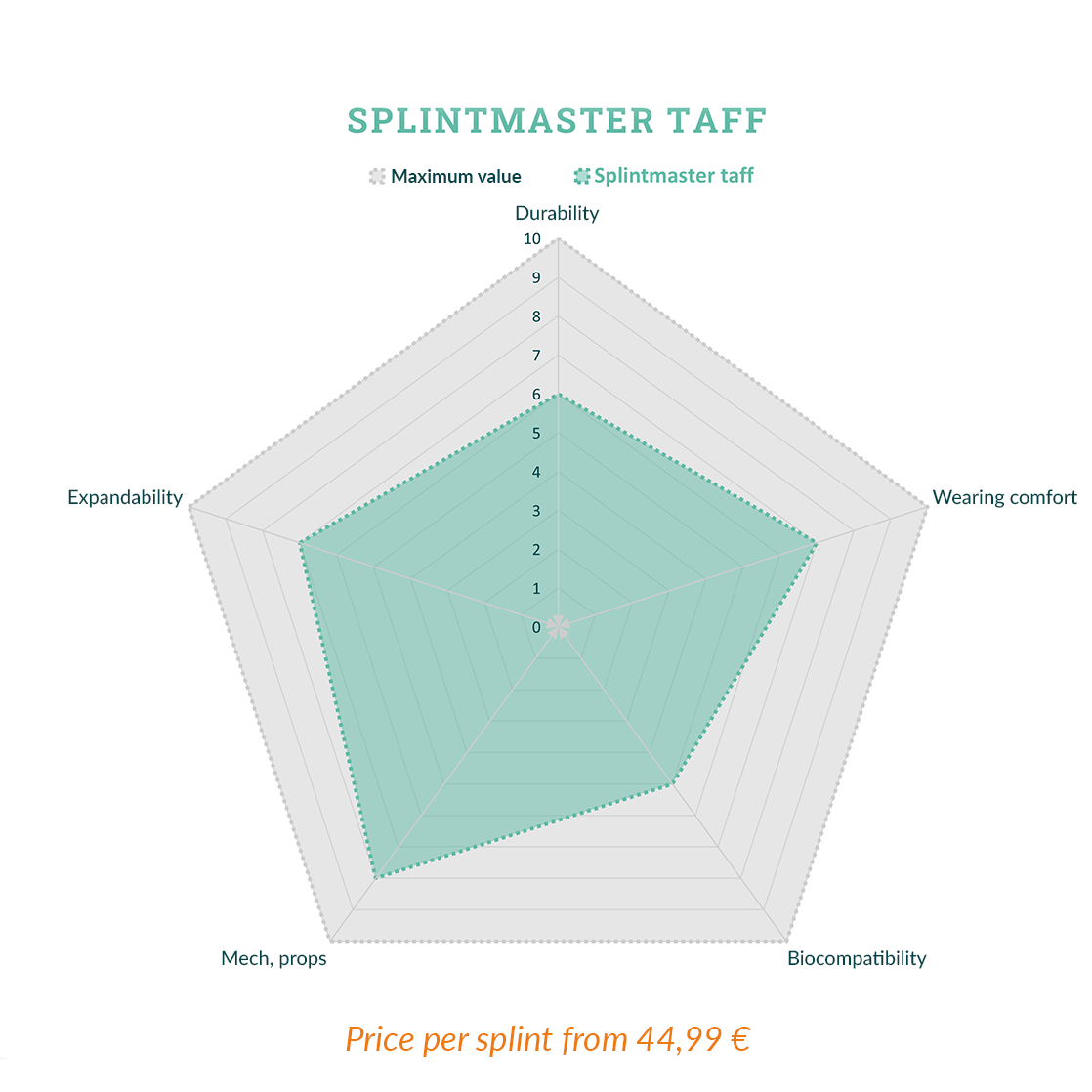

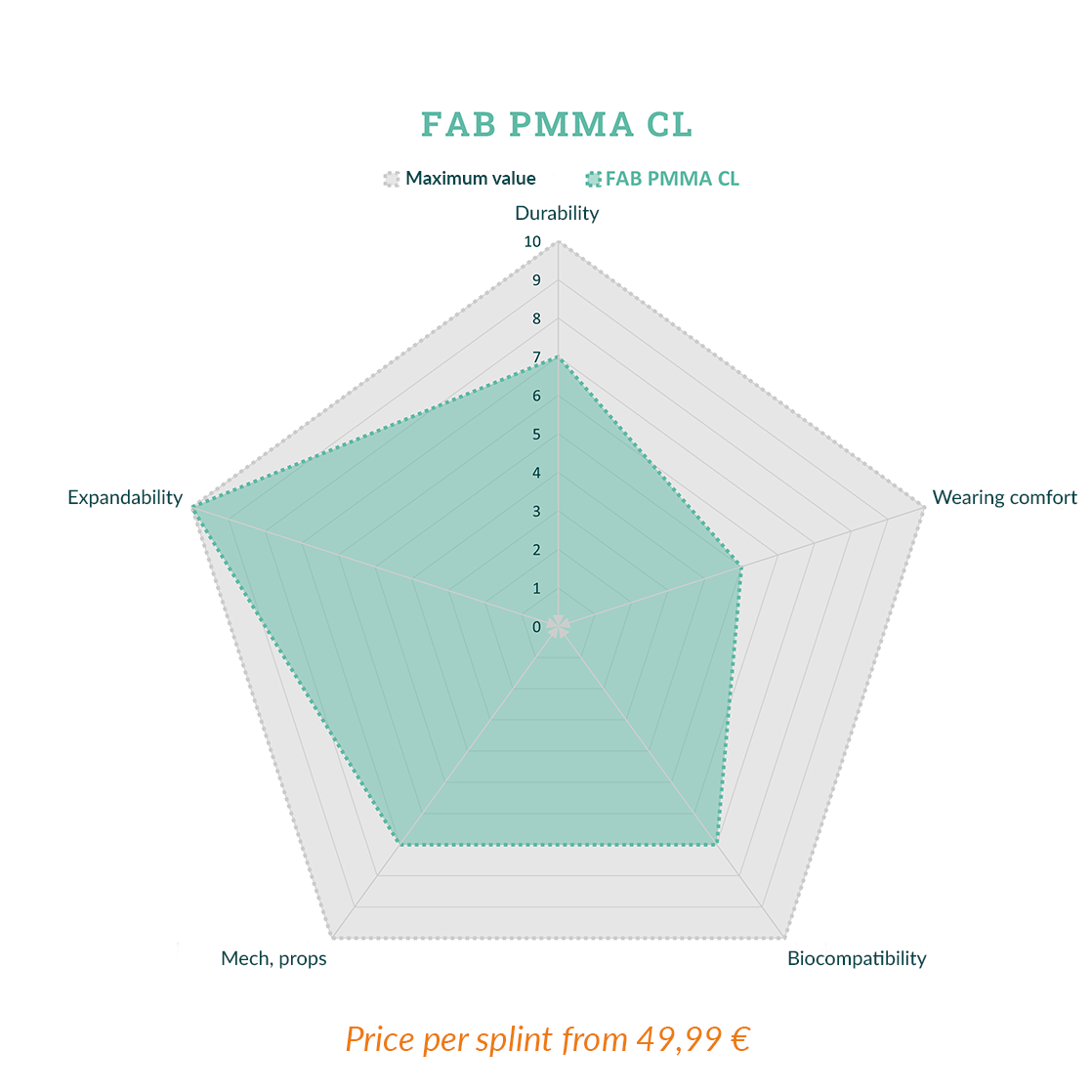

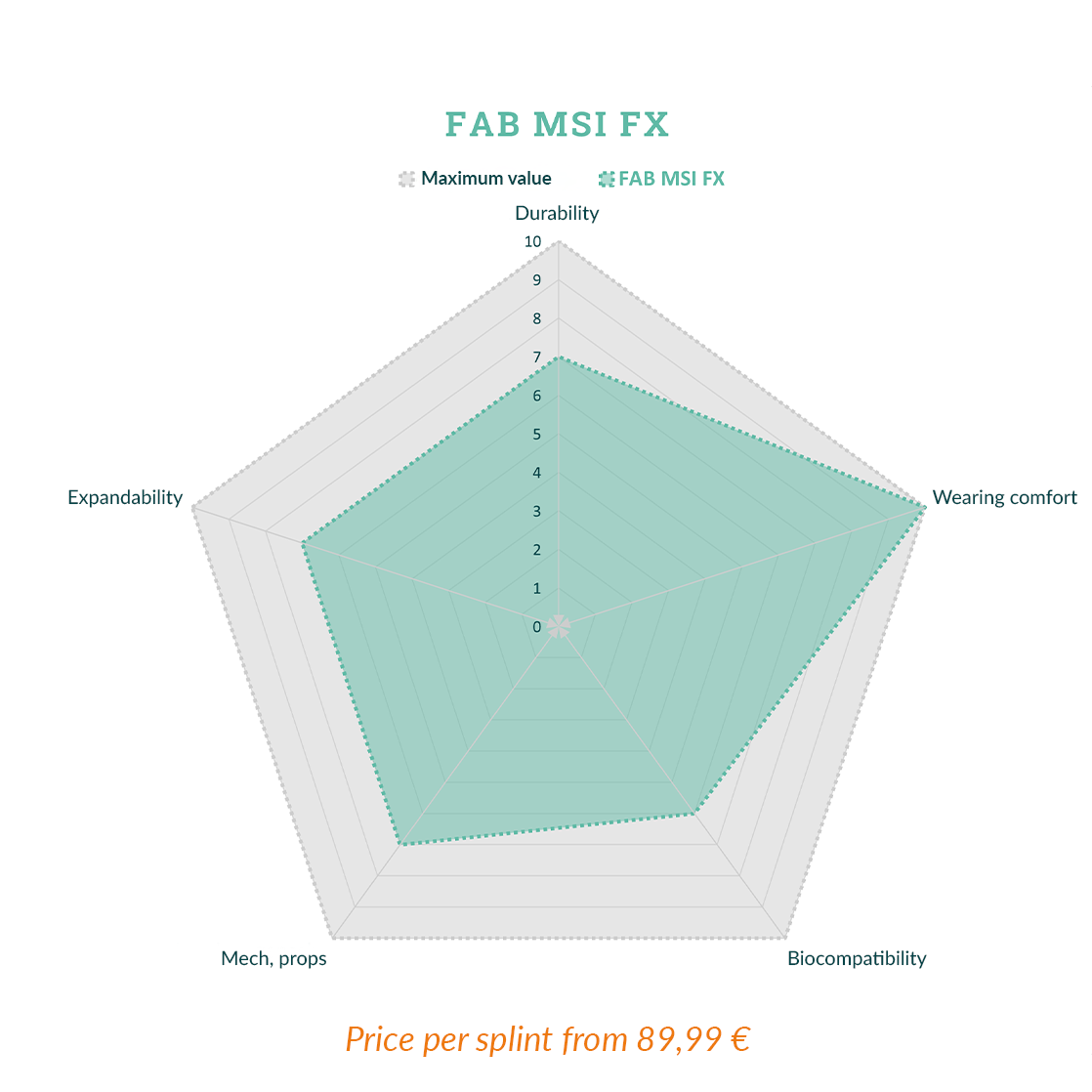

How does splintmaster taff compare to our milled splints?

We have created a qualitative comparison chart that shows you at a glance how our four splint options differ in terms of mechanical properties, biocompatibility, wearing comfort, expandability and durability.