Casting in silver and gold at CADdent - for high-quality pieces of jewelry

CADdent offers the option of casting jewelry in both silver and various gold alloys to meet the evolving requirements of the jewelry industry. In contrast to the LaserMelting process, which is primarily worthwhile for the production of large quantities, casting is a more efficient method, especially when it comes to the production of high-quality individual pieces or small series. Casting allows to realize very smooth surfaces, which are particularly important in the jewelry sector. This precise surface quality can be achieved with less manual effort than with additive manufacturing methods.

Flexibility through digital design

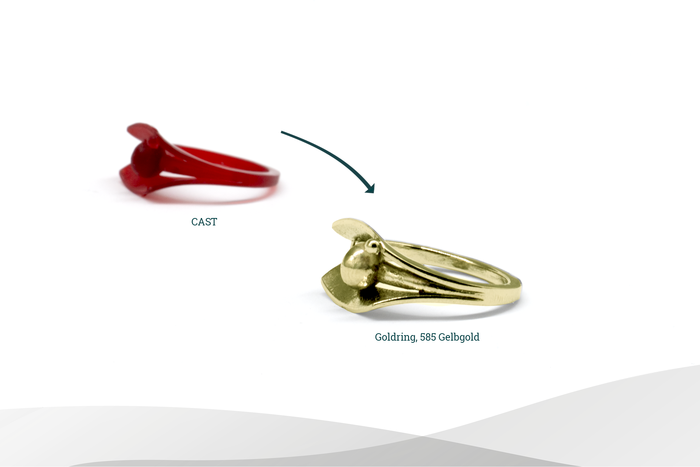

Another advantage of casting at CADdent is the combination of the benefits of digital design and traditional craftsmanship. The process begins with the digital modeling of the desired piece of jewelry, which allows the designer flexibility and creativity. Instead of manual modeling, the piece of jewelry is first created in a residue-free combustible plastic (CAST) using a 3D printing process. This plastic serves as a template for the subsequent casting mold. The printed model is embedded in a special investment material and then burned out. This creates an exact negative mold of the piece of jewelry into which various materials can be cast.

14-carat yellow gold: attractive in price and quality

In addition to silver, which is characterized by its classic properties and widespread use in jewelry manufacturing, CADdent also offers a range of gold alloys. Particularly popular is 14-carat yellow gold (585), which is highly valued by both jewelry designers and end customers due to its excellent price-performance ratio and warm colour. The flexibility of the casting makes it possible to choose from different precious metals, with CADdent offering both silver and a selection of gold alloys.

Order conveniently online

It was important for CADdent to make the ordering process as simple and efficient as possible. Therefore, weh ave introduced an automatic price calculation for 585 gold on our prototyping order page. This is particularly beneficial for those customers who regularly order jewelry made of materials such as silver, titanium or cobalt-chrome and now also see gold alloys as an interesting option. The automation eliminates the need to manually create a quote for each piece of jewelry, making the ordering process much easier for everyone involved.

CONCLUSION

Overall, the casting process at CADdent offers an attractive combination of state-of-the-art technology and traditional craftsmanship, making it possible to produce high-quality pieces of jewelry in silver or gold with maximum precision and efficiency. The flexibility in the choice of materials and the smooth surfaces achieved by casting make this process particularly interesting for designers who value customized and high-quality pieces of jewelry.