The art of dental design lies in the perfect combination of specialist knowledge and craftsmanship. At CADdent, we combine decades of experience with the latest innovations to always present you with top performance. To give you an insight into the depth of our craft, we would like to present seven fundamental aspects that are crucial to our work.

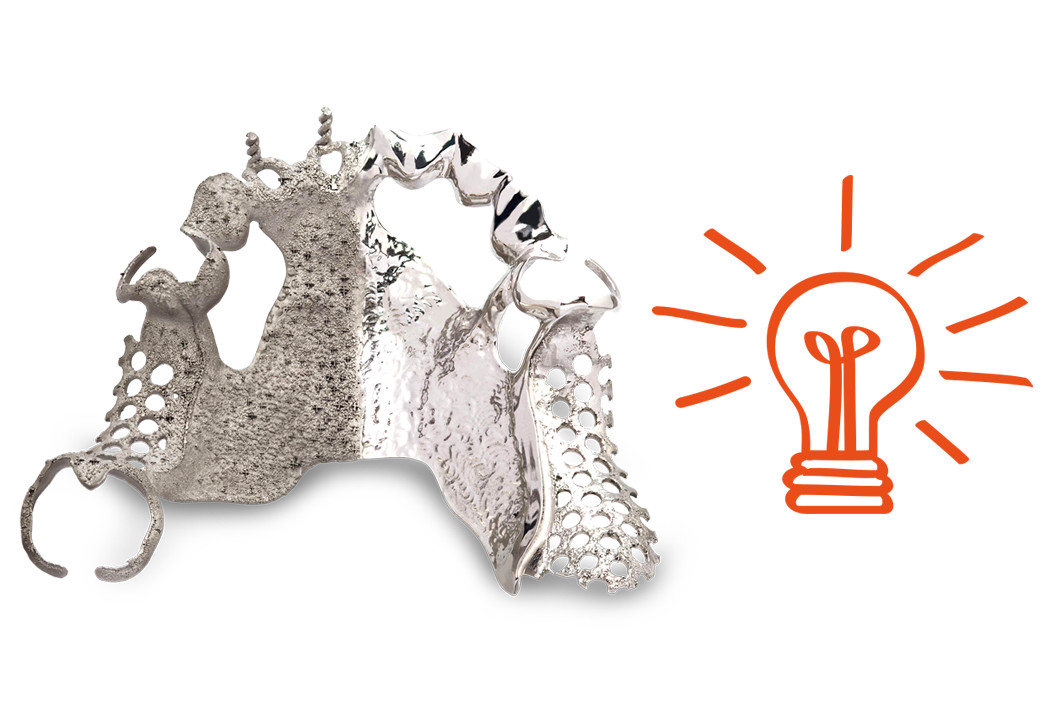

The rapid development of digital technologies has revolutionized almost all industries. In the partial framework (RPD) sector in particular, we have recognized the opportunities offered by digitalization and are using them to achieve groundbreaking results. The key to this? A deep understanding of the intricacies and nuances of digital partial framework (RPD). Let's dive together into seven essential tips that point the way to world-class digital partial framework (RPD) design.

1. Design according to parameters - the measure of all things:

When designing digital partial framework (RPD), it is very important to adhere correctly to the specified thicknesses for clasps, sublingual bars and palatal plates. A design which is too thick can impair wearing comfort. Clasps and sublingual bars which are too thick could also become too stiff and break more quickly. At the same time, failure to adhere to the specified thicknesses has a negative impact on the production process and the fitting process.

2. Clean basis - clear results:

Careful scanning is essential for a precise design. Too little scanning spray can lead to reflections, while too much creates a "furry" appearance which affects the design. Bubbles should be erased in advance to create a solid base for the rest of the process.

3. Smooth transitions with block-out wax:

Smooth transitions, achieved by carefully blocking out with wax, make it easier to fit the partial framework (RPD) onto the model and prevent annoying corners and edges.

4. Curved designs - appearance meets function:

A curve in a clasp not only looks aesthetically pleasing, but can also extend the spring deflection and make the clasp more functional. Inspired by nature, where nothing really grows straight and no fissure of an occlusal surface is straight, we avoid "fishhook" designs and focus on beautifully curved clasps.

5. Place the rests carefully - for a harmonious construction:

When placing the rests, it is important to position the ends so that clasps can connect seamlessly. An eye for detail, such as avoiding unsightly corners, not only ensures an aesthetically pleasing design, but also a more stable and graceful one.

6. Correctly block out interdental spaces with Neysteel clasps:

When working with Neysteel clasps, it is important to block out the interdental spaces. This protects against sharp edges and also makes it easier to adapt.

7. Insertion direction and clasps placement - the finer details count:

The correct setting of the insertion direction is crucial. Both quadrants should be evenly aligned. There should be less undercutting, especially in the anterior region, which is more visible, than the posterior one. Only about ⅓ of the clasp should be in the undercut, more precisely only the tip of the clasp and part of the lower arm. This ensures optimal function and prevents problems when adapting.

CONCLUSION

At CADdent, we attach great importance to consolidated specialist knowledge and continuous further development. With our experience and drive for innovation, we want to set new standards in dental technology. If you have any questions or are looking for support, we are always there for you.

The tips presented here will help you to produce convincing work in the field of digital partial framworks (RPD). The combination of traditional know-how and digital technology offers many opportunities. Let's use these opportunities together to achieve the best possible results for our patients.